Manufacturer of Pp Sheet Food Grade - PP Plastic Sheet – Qinghua

Manufacturer of Pp Sheet Food Grade - PP Plastic Sheet – Qinghua Detail:

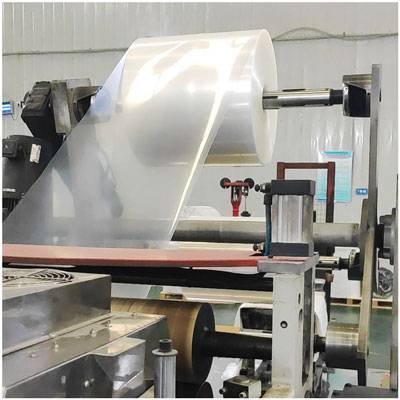

Multi-layer co-extrusion equipment could produce transparency .double color ,monochrome ,full color and various type of OO sheet .And the PP sheet apply to food packaging ,free tray ,disposablecups ,electronic packing ,disposable tableware and other series product .

1.Density

PP sheet is the minimum density of all sheets,only 0.90-0.93g/cm3, is about 60%of the density of PVC .This means with the same weight of raw material can produce more quantity same volume products .

2.Thermal properties

In the five general plastic ,PP thermo stability is the best .PP plastic products can work long hours under 100°c , in the absence of external force ,PP products will not deformation when heated to 150°c. After using nucleating agent improved the crystallization of PP ,its heat resistance can also be further improved ,can even make microwave heating food vessels.

3.PP for oxygen ,carbon dioxide and water vapor has certain permeability ,compared with nylon(PA)and polyester (PET)has obvious difference ,for high barrier property of plastic ,such as PVDC,EVOH,difference is larger .But compared with other non-plastic materials,its gas tightness is fairly good .By adding barrier property material or coating barrier property plastic on the surface ,could greatly improve its gas tightness.

PP sheet use to polypropylene resin as the main raw material. Add various process masterbatch toughening agent and brightening agent.production by mixing,plastic plastifying extrusion,Three-roll calendering,cooling,traction and rolling-up.PP sheet has the characteristics of non-toxic, tasteless, sanitary, high mechanical strength and good resistance, that’s can be used for packaging of industrial, agricultural and fruit industries.

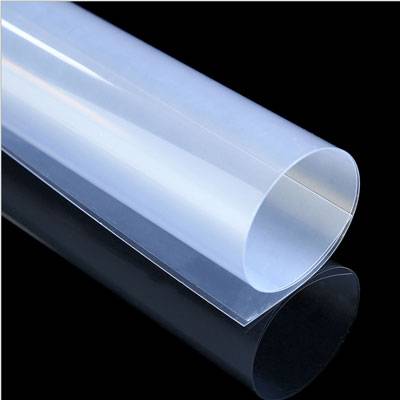

PP sheet not only non-toxic, tasteless, sanitary, high mechanical strength and good resistance,And it can be recycled.No poisonous or harmful gases are produced when heated or burned,not endanger human helath,no erode equipment,This Is a new type of green packaging materials.PP sheet can be made into various products through secondary processing such as thermal forming.mainly applied Packaging of food, medicine and medical equipment. it can be used for food packaging by processing jelly box, dairy packaging box, fast food box, cold drink container, tray, microwave oven appliance and etc;Processed into bubble caps can be used for pharmaceutical tablets, capsules and other solid preparations Packaging.In foreign countries, especially in developed countries and regions, transparent PP sheet is widely used in food packaging.

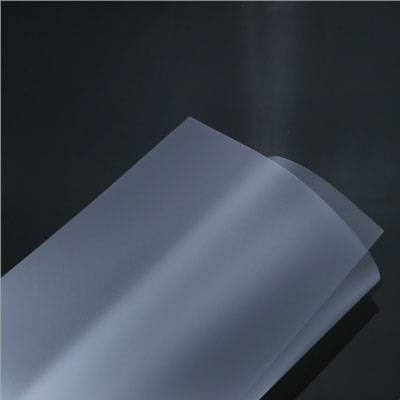

PP Plastic Product Characteristics : environmental feature、aesthetics、screen printing、gilding、high temperature resistance、low temperature resistance、high transparency、resistance to bending is easy to fold、can microwave, The products meet the food testing standards.

Our company can also produce PP special sheet for cup making machine, which is suitable for disposable water cup, milk tea, jelly cup, packing box and other container products.This kind of sheet can be microwave resistant, low temperature resistant, high transparency, and can withstand large stretch.

Packaging Details: Common Antistatic PS sheets & rolls are packed by cellophane & film and fastened by strape, and then put them on standard container pallet

Covered with craft paper or PE film on double sides with pallet

Bulk cargo packing: 2 tons per tray, use wooden pallets on bottom, with packaging film packages all around ensure transportation security.

Full container load packing: 18-20 tons of a 20 foot container with 10 tray.

|

Range of production |

|

| Width | 280mm-900mm |

| Thickness | 0.23mm-2.2mm |

| Colour | All kinds of normal colors are available |

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Manufacturer of Pp Sheet Food Grade - PP Plastic Sheet – Qinghua , The product will supply to all over the world, such as: Finland, Romania, Mumbai, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer's requirement.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!