Wholesale Price 0.3mm pet film - PET Plastic Sheet with PE Coating – Qinghua

Wholesale Price 0.3mm pet film - PET Plastic Sheet with PE Coating – Qinghua Detail:

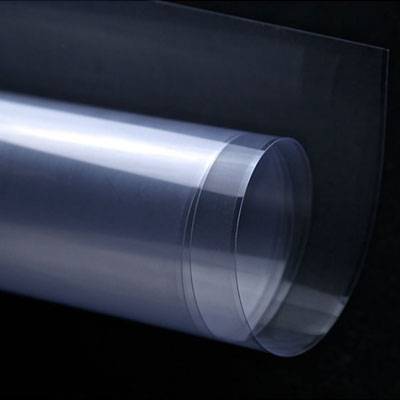

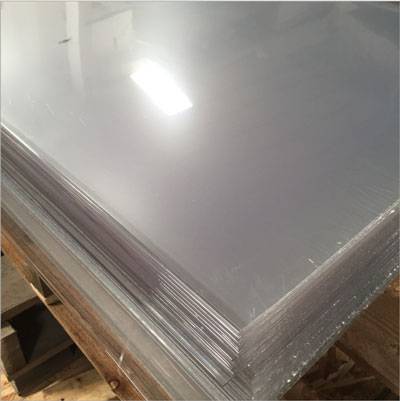

PET coated film plastic sheet

Our factory can produce the PET coating films one size and both side.

Sheet( PET SHEET) also known as hard polyester fabric, thermoplastic products. The scrap and waste recyclable, the chemical elements with paper carbon, hydrogen, oxygen, belonging to the degradable plastics. Packaging products made of this material discarded eventually into the water and carbon dioxide. A-PET environment protection film is widely used in cosmetics, food, electronics, toys, printing and other industries packaging. Such as various kinds of blister packaging, folding box, rubber tube, window film etc.

Application:

APET environmental protection film is widely used in cosmetics, food, electronics, toys, printing and other industries packaging. Such as various kinds of blister packaging, folding box, rubber tube, window film etc.

Advantages:

Compared with the widely used PVC film, A-PET has the following advantages:

1.The proportion of light: the proportion of PET than PVC 1.33,1.38,3.7% lower proportion

2.2. High strength: PET film strength than PVC film is more than 20% higher, low-temperature impact resistance performance is better, -40℃ capability brittle, so we usually use thinner than 10% film to replace PVC.

3.Good folding endurance. PET film does nor appear crease since crack like PVC, more suitable for the surface decoration of file etc.

4.APET film (PVC film with high transparency, especially shiny bluish) than the PVC film is good, more suitable for the exquisite packaging.

5.APET products without pollution, crystal, high transparency, good smoothness, strong impact resistance, can widely film according to customer requirements.

Features:

1.high transparency, glossy highlights;

2.good toughness, no crystal point, no water ripple, two-way no fold white;

3.With characteristics of heat resistance and chemical corrosion resistance;

4.Superior optical performance (High light transmittance, High smoothness and low halo), Outstanding printability, can be directly used for offset printing;

5.With outstanding toughness and high impact strength. Its impact strength is 3~10 times that of modified polyacrylates, and its molding performance is excellent.

6.can be used for food, medical device packaging.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for Wholesale Price 0.3mm pet film - PET Plastic Sheet with PE Coating – Qinghua , The product will supply to all over the world, such as: Morocco, Nigeria, Surabaya, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.